We are doing Design & Engineering , Manufacturing of Industrial Equipment's Since 1996. We also do Industrial Plant Maintenance Services Offer full-service industrial process maintenance agreement, we’ll take over complete and total responsibility for the Engineering, Planning, and Executing of your plant's maintenance tasks to meet your fullest satisfaction.

We have highly skilled Team of Well trained Technicians & Site Engineers to carry out the jobs even at remote sites without much difficulty.

Blue Green Engineering Technologies continues to provide specialized industrial maintenance services to meet requirement of Industries & corporate clients. We operate from a core philosophy of adding value to our client's business by providing solutions to their difficult problems.

Industries that want to remain efficient need to maintain their plants and machines continually and have them replaced by new ones if necessary. Production facilities should be made optimal use of, and unplanned production downtime should be avoided.

We do all kinds of Plant Modifications & extensions and all kinds of repairing services for the industrial needs for Plant shut down requirement. Please register our name in your vendors list for sending your valuable needs in near future.

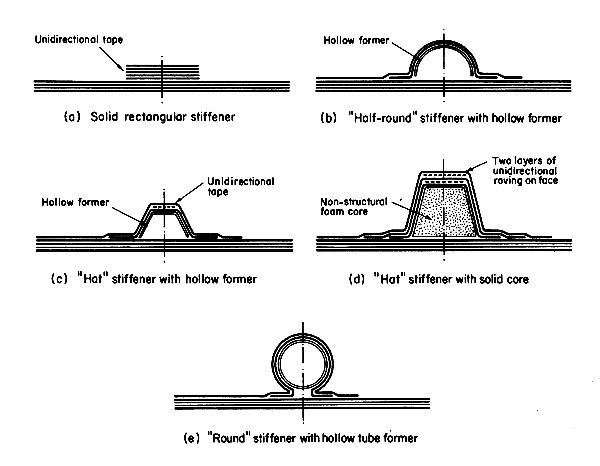

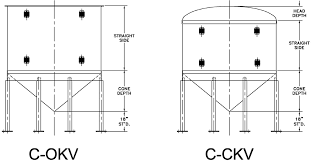

WE DO DESIGN,ENGINEERING AND MANUFACTURE FRP TANKS IN VARIETY OF SIZES ACCORDING TO TANKS INTENDED APPLICATION AND CUSTOMERS SPACE REQUIREMENTS.. CUSTOMERS CAN SELECT WIDE RANGE OF DIAMETERS IN ADDITIONS TO ORIENTATION AND HEIGHT (VERTICAL TANKS) LENGTH ( HORIZONTAL TANKS) AND CAPACITY.

WE MAKE PVDF PPH PP ECTFE TANKS AND LINER ACID ALKALI PROOF PIPES AND FITTINGS.

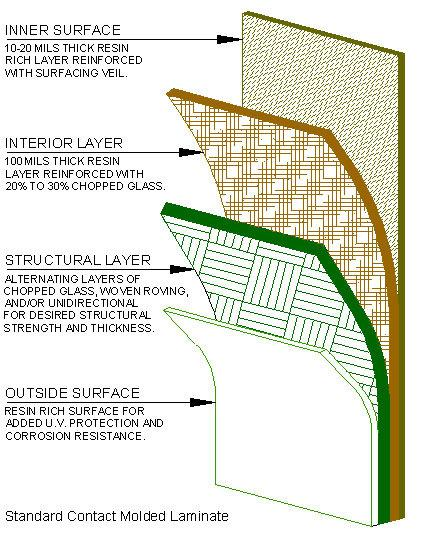

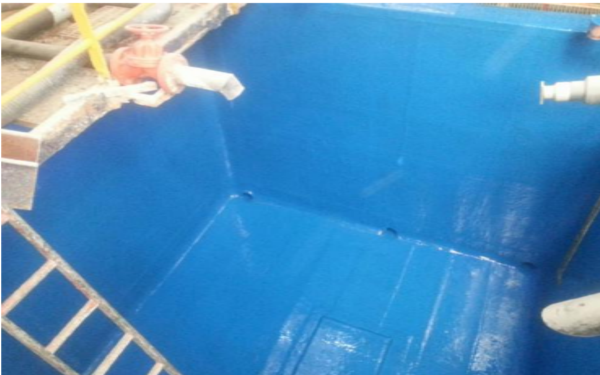

WE DO ON SITE F.R.P ACID PROOF LINING ON TANK INNER AND OUTER SURFACE TO PROTECT FROM CORROSION WITH HIGH QUALITY RAW MATERIALS TO MEET BEST PERFORMANCE FOR DECADES.

WE MANUFACTURE TANKS TO MEET STANDARDS ASTM D 4097 / PS 15-69 , BS 4994 FOR CONTACT MOLDING OR ASME RTP—1.

WE @ I.T.E. MANUFACTURE TANKS WITH PROPER DESIGN AND ENGINEERING ACCORDING TO THE MEDIA TO BE HANDLED IN THE TANKS ,INTERNAL AND EXTERNAL LOAD CONDITIONS TO HAVE THE BEARING CAPACITY OF THE TANKS TO SERVE THE INDUSTRY TO THE ENTIRE DESIGN LIFE OF 25 YEARS WITH SUPERIOR QUALITY RAW MATERIALS TO MEET THE HIGHEST PERFORMANCE IN CONTINEOUS PROCESS INDUSTRIES. OUR TANKS ARE FIT AND FORGET TYPE MAINTENANCE FREE TANKS.

WE MAKE BIO GAS TANKS FOR POWER PRODUCTION PROCESS AND OUR TANKS ARE HIGH QUALITY TO MEET THE MAXIMUM GUARANTEE OF 10 YEARS FROM THE DATE OF SUPPLY.

WE @ ITTE MANUFACTURE HIGH PERFORMANCE HEAVY DUTY BULK STORAGE TANKS SUCH AS 100 KL , 200 KL, 300 KL TANKS IN SINGLE PIECE CONTACT MOLD TECHNIQUE WITH HEAVY DUTY DESIGN & ENGINEERING. (BELOW FIG SHOWS 150 KL TANK.)

B.G.E.T — R.T.R.P / FRP ANTICORROSION LINING SYSTEM TO PROTECT RCC TANKS AND MILD STEEL MACHINERIES FROM CORROSION PROBLEMS.

HEAVY DUTY PULP /CHEMICAL STORAGE TANKS

The solution – Simple! - We offer you a trouble-free roof, which will not only have a catchy appearance, but will also give you a warranty for up to 5 years!

Want to make this your last metal roof repair ever??

Then choose our High Performance Heavy duty INNO COAT innovative metal roof coating system. Our system not only fixes your prevailing problems, but also ensures that you get a leak free roof for decades without any maintenance .

Many Commercial /Industrial organizations have our superior metal roof coatings in their structures.

We have hundreds of satisfied clients who know that we offer only permanent, not patchy roof installations .

We utilize your existing roof. You get repair and renovation all in one.

We provide such thorough preparation of your metal roof that your current problems are dealt with before the permanent solution – the coating – is applied. We perform five levels of metal roof repair (metal restoration):It’s called a Metal Roof Restoration System® (MR): Your roofing problems will be solved when we install our High Performance Heavy duty INNO COAT ROOF SEAL Coating Systems. Too often, the advice you’ll get about metal roof repair is that the roof “has to come off” because it is not repairable. But in real every roof system will come back strong with high durability with our roof coating system.

Metal Roof Restoration System (MR) – This involves five levels of roof repairs before we finally install our High Performance Heavy Duty INNO COAT ROOF SEAL coating. We never advise our clients to replace the existing roof; on the contrary, the existing roof, with the aid of our innovative coating methods, will turn into a strong and durable product with an absolute new look!

MAJOR ADVANTAGE : your permanent metal roof repair will end up paying for itself in utility cost savings. The top coat is designed to be reflective. This is the most Innovative “ go green” technology that causes the sun’s energy to bounce off, rather than be absorbed and then passed into your building. When your metal roof is that much cooler, demand for interior cooling goes down. Independent testing of reflective roofing discovered it can reduce the 7 to 10 % cost air conditioning.

Your new roof surface will be total 100 % rust free because a specially-formulated oxidation inhibitor is Laminated. Most leaks are at a seam. We caulk every inch of seam to eliminate existing leaks, and then laminate our INNO COAT ROOF SEAL, for a true bonded seal. Chances are a leak has made metal roof repair an immediate concern. Or, a storm has loosened panels or blown them off. Any problem with loose panels is resolved because we re-tighten or replace every one of the hundreds of screws common on a metal roof and all screws will be laminated properly with perfect sealing.

We are Technocrats Executing Industrial Corrosion Management doing Industrial Design & Engi- neering Services in Fabrication and Erection services Since 1996. We @ I.T.E. . specializing Corro- sion in Huge RCC TANKS, ANODIZING,ELECTROPLATING FLOORINGS , SHOP FLOORS RCC TOW- ERS and RCC SOLAR PONDS etc. by our specialized RTRP THERMOPOLYMER ACID ALKALI PROOF Industrial Lamination Protection Services to the fullest satisfaction with High Quality Raw material at Cost Effective solution to meet the Highest life cycle Industries at ETP department solar ponds and Trenches ETP COLLECTION PITS and Acid Storage tank are a floor lining system and DM / RO PLANT TRENCHES AND FLOOR areas with High Quality job finish.

We are Technocrats Executing Industrial Corrosion Management doing Industrial Design & Engi-

neering Services in Fabrication and Erection services Since 1996. We @ I.T.E. . specializing Corro-

sion in Huge RCC TANKS, ANODIZING,ELECTROPLATING FLOORINGS , SHOP FLOORS RCC TOW-

ERS and RCC SOLAR PONDS etc. by our specialized RTRP THERMOPOLYMER ACID ALKALI PROOF

Industrial Lamination Protection Services to the fullest satisfaction with High Quality Raw

material at Cost Effective solution to meet the Highest life cycle Industries at ETP department solar

ponds and Trenches ETP COLLECTION PITS and Acid Storage tank are a floor lining system and

DM / RO PLANT TRENCHES AND FLOOR areas with High Quality job finish.

We also doing F R P Lining in Water drain areas such as Gutters and Roofing structures

etc. We are manufacturing F R P Heavy duty Pipes and fittings to meet client

requirement in critical application such as Acids with highly corrosive nature to transfer

safely with trouble free system for decades.

I.T.E. — HIGH PERFORMANCE ELECTROPLATING, ANODIZING, PICKLING AND PASSIVATION TANKS ARE MADE WITH IN BUILT DUCTING SYSTEM TO RECOVER FUMES DURING OPERATING PROCESS WITH HIGH EFFICIENCY VENTURY DUCTS.

I.T.E. - ELCTROPLATING, ANODIZING,PICKLING AND PASSIVATION RINSE BATH TANKS ARE MANUFACTURED WITH THE SUPERIOR THERMOPLASTIC MATERIALS TO MEET THE CRITICAL CHEMICAL HOLDING AND PROCESSING WITH EXCESSIVE TEMPERATURE APPLICATIONS AS REQUIRED BY THE PROCESS SO THAT THE EQUIPMENT IS DESIGNED AS PER CLIENTS EXACT REQUIREMENT KEEPING IN VIEW OF THEIR OPERATING CONDITIONS SUCH AS MEDIA TO BE HANDLED AT ITS CONCENTRATION SP.GRAVITY AND TEMPRETURE REQUIREMENT IN THE SYSTEM WITH THE PROPER DESIGN AND ENGINEERING TO OBTAIN EFFECTIVE LIFE OF THE EQUIPMENT TO MEET THE HIGHEST STANDARDS.

I.T.E - PLATING TANKS WILL BE MANUFACTURED AS PER CUSTOMERS REQUIREMENT OF SIZES AND SHAPES.

I.T.E - ACID / ALKALI PROOF INDUSTRIAL FLOORINGS WILL GIVE EXCELLENT LIFE FOR YEARS 100 % ANTICORROSION PROPERTIES WITH HIGH DURABILITY TO MEET CRITICAL CONDITIONS WITHOUT TROUBLE. WE MANUFACTURE JOINT FREE (R.T.R.P) AND NEGLIGIBILE JOINT (PPHGL / RTRP) ACID PROOF FLOORINGS ACCORDING TO THE MEDIA TO BE HANDLED AND SYSTEM REQUIREMENT AT CLIENT SITE CONDITIONS. OUR ACID PROOF SYSTEM IS GUARANTEED UP TO 5 YEARS.

We are Technocrats manufacturing, supply and Installation of High Performance Heavy duty Industrial Molasses tanks from 100 MT to 12000 MT all over India meet clients fullest satisfaction.

Molasses last long time with proper storage. Heat and Humidity can cause molasses to get moldy so store it in a cool dry place and be sure it is tightly closed. It can be stored for a long period without deterioration providing dilution does not occur as the dilution leads to get molasses ferment fairly quickly. Storage tanks must be constructed so that water cannot get in and tanks should be vented to prevent condensation taking place and diluting the surface of the molasses. An adequate system of ventilation also helps to prevent better storage of molasses.