MAJOR ADVANTAGE : your permanent metal roof repair will end up paying for itself in utility cost savings. The top coat is designed to be reflective. This is the most Innovative “ go green” technology that causes the sun’s energy to bounce off, rather than be absorbed and then passed into your building. When your metal roof is that much cooler, demand for interior cooling goes down. Independent testing of reflective roofing discovered it can reduce the 7 to 10 % cost air conditioning.

Your new roof surface will be total 100 % rust free because a specially-formulated oxidation inhibitor is Laminated. Most leaks are at a seam. We caulk every inch of seam to eliminate existing leaks, and then laminate our INNO COAT ROOF SEAL, for a true bonded seal. Chances are a leak has made metal roof repair an immediate concern. Or, a storm has loosened panels or blown them off. Any problem with loose panels is resolved because we re-tighten or replace every one of the hundreds of screws common on a metal roof and all screws will be laminated properly with perfect sealing.

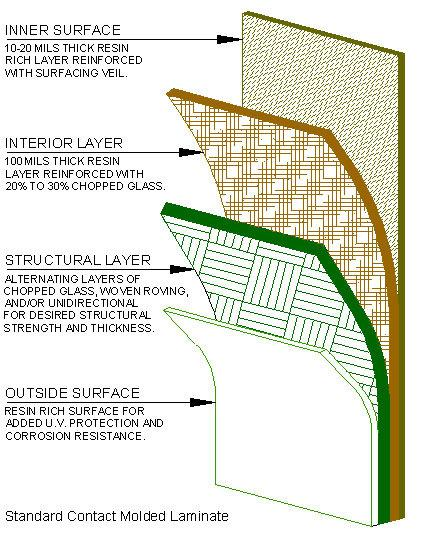

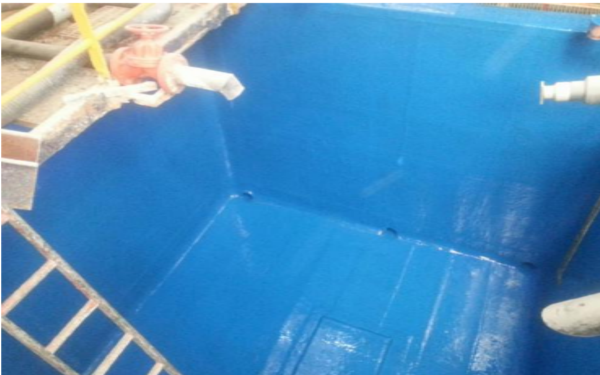

We are Technocrats Executing Industrial Corrosion Management doing Industrial Design & Engi- neering Services in Fabrication and Erection services Since 1996. We @ I.T.E. . specializing Corro- sion in Huge RCC TANKS, ANODIZING,ELECTROPLATING FLOORINGS , SHOP FLOORS RCC TOW- ERS and RCC SOLAR PONDS etc. by our specialized RTRP THERMOPOLYMER ACID ALKALI PROOF Industrial Lamination Protection Services to the fullest satisfaction with High Quality Raw material at Cost Effective solution to meet the Highest life cycle Industries at ETP department solar ponds and Trenches ETP COLLECTION PITS and Acid Storage tank are a floor lining system and DM / RO PLANT TRENCHES AND FLOOR areas with High Quality job finish.

We are Technocrats Executing Industrial Corrosion Management doing Industrial Design & Engi-

neering Services in Fabrication and Erection services Since 1996. We @ I.T.E. . specializing Corro-

sion in Huge RCC TANKS, ANODIZING,ELECTROPLATING FLOORINGS , SHOP FLOORS RCC TOW-

ERS and RCC SOLAR PONDS etc. by our specialized RTRP THERMOPOLYMER ACID ALKALI PROOF

Industrial Lamination Protection Services to the fullest satisfaction with High Quality Raw

material at Cost Effective solution to meet the Highest life cycle Industries at ETP department solar

ponds and Trenches ETP COLLECTION PITS and Acid Storage tank are a floor lining system and

DM / RO PLANT TRENCHES AND FLOOR areas with High Quality job finish.

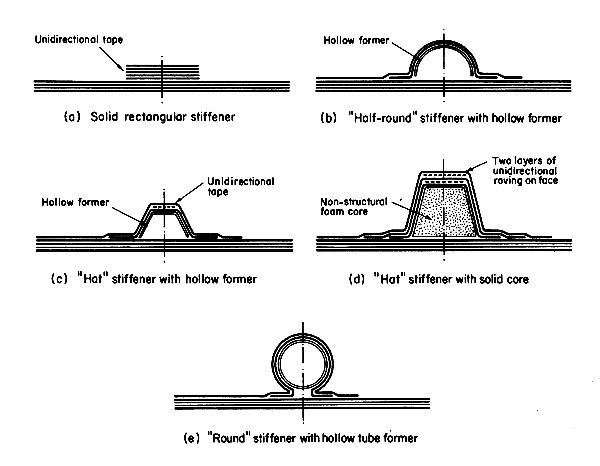

We also doing F R P Lining in Water drain areas such as Gutters and Roofing structures

etc. We are manufacturing F R P Heavy duty Pipes and fittings to meet client

requirement in critical application such as Acids with highly corrosive nature to transfer

safely with trouble free system for decades.

I.T.E. — HIGH PERFORMANCE ELECTROPLATING, ANODIZING, PICKLING AND PASSIVATION TANKS ARE MADE WITH IN BUILT DUCTING SYSTEM TO RECOVER FUMES DURING OPERATING PROCESS WITH HIGH EFFICIENCY VENTURY DUCTS.

I.T.E. - ELCTROPLATING, ANODIZING,PICKLING AND PASSIVATION RINSE BATH TANKS ARE MANUFACTURED WITH THE SUPERIOR THERMOPLASTIC MATERIALS TO MEET THE CRITICAL CHEMICAL HOLDING AND PROCESSING WITH EXCESSIVE TEMPERATURE APPLICATIONS AS REQUIRED BY THE PROCESS SO THAT THE EQUIPMENT IS DESIGNED AS PER CLIENTS EXACT REQUIREMENT KEEPING IN VIEW OF THEIR OPERATING CONDITIONS SUCH AS MEDIA TO BE HANDLED AT ITS CONCENTRATION SP.GRAVITY AND TEMPRETURE REQUIREMENT IN THE SYSTEM WITH THE PROPER DESIGN AND ENGINEERING TO OBTAIN EFFECTIVE LIFE OF THE EQUIPMENT TO MEET THE HIGHEST STANDARDS.

I.T.E - PLATING TANKS WILL BE MANUFACTURED AS PER CUSTOMERS REQUIREMENT OF SIZES AND SHAPES.

I.T.E - ACID / ALKALI PROOF INDUSTRIAL FLOORINGS WILL GIVE EXCELLENT LIFE FOR YEARS 100 % ANTICORROSION PROPERTIES WITH HIGH DURABILITY TO MEET CRITICAL CONDITIONS WITHOUT TROUBLE. WE MANUFACTURE JOINT FREE (R.T.R.P) AND NEGLIGIBILE JOINT (PPHGL / RTRP) ACID PROOF FLOORINGS ACCORDING TO THE MEDIA TO BE HANDLED AND SYSTEM REQUIREMENT AT CLIENT SITE CONDITIONS. OUR ACID PROOF SYSTEM IS GUARANTEED UP TO 5 YEARS.

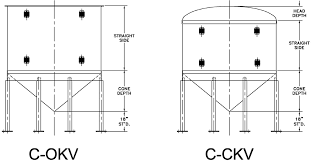

We are Technocrats manufacturing, supply and Installation of High Performance Heavy duty Industrial Molasses tanks from 100 MT to 12000 MT all over India meet clients fullest satisfaction.

Molasses last long time with proper storage. Heat and Humidity can cause molasses to get moldy so store it in a cool dry place and be sure it is tightly closed. It can be stored for a long period without deterioration providing dilution does not occur as the dilution leads to get molasses ferment fairly quickly. Storage tanks must be constructed so that water cannot get in and tanks should be vented to prevent condensation taking place and diluting the surface of the molasses. An adequate system of ventilation also helps to prevent better storage of molasses.