We @ INNOVATIVE TECH TRICS EQUIPMENTS MANUFACTURING HIGH PERFORMANCE HEAVY DUTY EQUIPMENTS SINCE 1996 ITSELF. I.T.T.E MANUFACTURING THE MOST INNOVATIVE HIGH PERFORMANCE STORAGE EQUIPMENTS BY IMPLETMENTING THE ADVANCED TECHNOLOGY.

we @ i.t.t.e design, engineering and manufacture high performance heavy duty g.r.p water storage above ground and u.g. sumps in variety of sizes according to tanks intended application and customers space requirements. customers can select wide range of sizes and shapes in additions to orientation and height (vertical tanks) length ( horizontal tanks) according to their volumetric capcity requirements.

our tanks are tailer made so it can be made according to clients exact size and shape requirement according to the space availability at site.

TYPES OF G.R.P TANKS :

Conventional type g.r.p panel tanks are being used to store huge water at present all over the coutry which is being build by numberous internals such as tie rods and fasteners gaskets etc to obtain leak proof performance.

But unfortunately all the internals damaged by water corrosion and simply fail within months also in some cases this depends upon the water quality.

Glass fibre reinforced plastic has a very low thermal conductivity. the actual value is 1/240 of the value of steel. a typical problems with steel tanks , vessels has always been the high thermal conductivity and expansion of co - efficient of steel.

These characteristics can cause loosening the g.r.p panels connecting bolts in areas of wide temperature change re- sulting in leaking and cracking grp panels however not affected to such a high degree.

External reinforcement ensures addiitional strength and high and heavy duty performance.

Our tanks can be used underground applications.

We manufacture high performance heavy duty molded type grp tanks with high quality raw materials to meet the highest performance to the entire satisfaction of end users.

Our tanks totally free of internals as our tanks are supported by mild steel stiffeners externally and most importantly all the mild steel stiffeners being used in the system are also being protected by anti- anti - corrosion lining system by encapsulation process.

We manufacture high performance heavy duty molded type grp tanks with high quality raw materials to meet the highest performance to the entire satisfaction of end users.

Our tanks totally free of internals as our tanks aresupported by mild steel stiffeners externally and most importantly all the mild steel stiffeners being used in the system are also being protected by anti - corrosion lining system by encapsulation process.

Our high performance heavy duty grp tanks are totally maintenance free trouble free corrosion free with high durability and long life cycle with cost effective solution.

I.T.T.E.— Engineering Plastics Composite Fiberglass Gutters are made by CONTACT MOLD TECHNIQUE to obtain joint free fine mere glass finish on inner most surface and these High Performance gutters are specifically designed for the application in Industrial Sheds Roofing in order to drain out the rainwater with a systematic manner of satisfying all the queries to the Civil Engineering.

w e @ itte design, engineering and manufacture high performance heavy duty septictanks two types in variety of sizes according to tanks intended application and customers space requirements.. customers can select wide range of sizes and shapes in additions to orientation and height (vertical tanks) length ( horizontal tanks) and capacity.

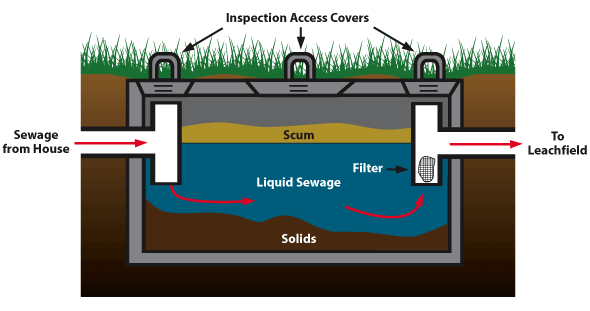

I.T.T.E sep!c tanks was originally designed to serve as a se0ling basin to separate scum and grit from the liquid. The effluent from the tank then was sent to a sewer or the soil for disposal

The clarification function of the tank was known, but the biological processes that partially digested sewage were discovered it is found that the organic solids in the wastewater decomposed if they stayed in the tank long enough. Therefore, the septic tank is designed to accomplish two tasks: (1) Clarification , (2) Treatment.

Clarification is a function of the detention time and the water extraction method. Solids settle out of the water based on size and specific gravity.Smaller lighter particles take longer to settle than heavier particles.Clarification also includes the removal of fats, oils and greases, which float to the surface along with soapsuds and “scum”.The variables of a septic tank are: size, shape, number of chambers, number and style of baffles and gas venting provisions.

Efficient clarification takes time to complete because fats, oils, greases, and suspended solids travel

slowly in water and may require hours to either float to the top or settle to the bottom.

The shape of the tank must be designed to maximize the detention time of the wastewater.

Surface area is more critical for settle ability than depth, so a shallow, wide tank is preferable to a deep,

narrow tank if both have the same volume capacity. Shallow tanks are also easier to transport and install

and poses less of a safety risk because the content level of the tank is not much deeper than the height

of an average person.

An improperly configured tank will allow wastewater to “short-circuit” through the tank to the outlet.

Short-circuiting can allow solids to migrate to the absorption field if the wastewater is not given sufficient

time for the solids to settle out.